Stainless Steel Labels

When the application environment gets really tough, and a long lifespan is crucial Stainless Steel is the permanent solution. Our imaged Stainless products are 316 2B grade a for superior corrosion, chemical and UV resistance.

- Asset tracking labels and tags.

- Compliance and rating plates.

- Nameplates and serial labels.

- Control fascia and mimic panels.

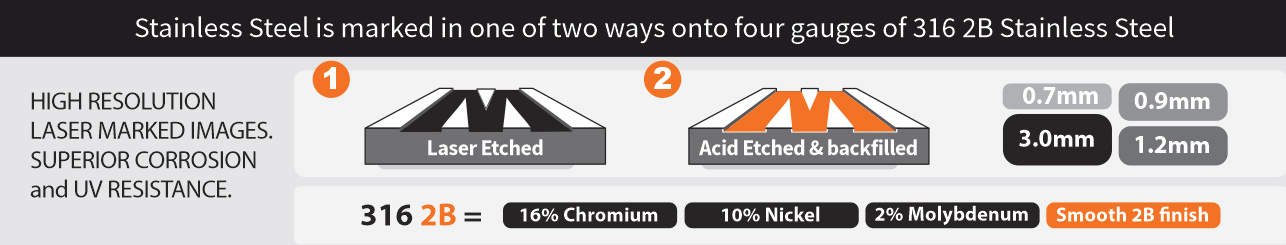

Laser Etched – High resolution images in black and contrast white. Almost indestructible, resists extreme heat and impact damage. Impervious to all but a few chemicals. The metal surface is vaporised and carbonised leaving a lightly etched black image or a contrast white image. By increasing power and reducing speed a deeper even more durable etch is possible.

Etched & backfilled – Chemically etched typically to 0.25mm, then backfilled to add colour before baking. A truly timeless image, the Titan of Identification. Not for the fiscally fainthearted.

Why Stainless Steel?

- Meets specifications for military, medical, food and chemical processing.

- 316 2B Stainless Steel for superior corrosion and unbeatable UV resistance.

- Essential in wash-down areas with 10% or greater caustic concentration.

- Withstands temperatures in excess of 400°C for extended periods.

- High contrast bar and QR codes for reliable scanning time after time, year after year.

- Super high-resolution laser images both front and backside.

- Laser cut in standard or custom sizes and shapes to create single and double sided tags.

- From thin to self-supporting thicknesses – available in 0.70, 0.90, 1.2 and 3mm gauges.

- Add your variable info by laser, rotary engraving, traditional stamping or dot peen marking.

We recommend you consider Anodised Aluminium if:

- There will be no food contact.

- You do not expect concentrated chemical or extreme temperature exposure.

- You don’t need the image to resist fading due to UV exposure longer than 25 years.

- This is typically an industrial product, so if looking beautiful is important let us know.

FAQ's

What’s the difference between 304 and 316 stainless steel? 304 contains 18% chromium and 8% nickel while 316 contains 16% chromium, 10% nickel and 2% molybdenum. The molybdenum is added to help resist corrosion to chlorides such as sea water.

What does 2B mean? A smooth, moderately reflective general-purpose metal finish.

Why is Stainless steel stainless? Because it is sufficiently reactive with the environment to protect itself from attack by forming an invisible passive corrosion layer. While this layer can be scratched, it will reform.