Stainless Steel Labels

When the application environment gets really tough, and a long lifespan is crucial Stainless Steel is the permanent solution. Our imaged Stainless products are all marine grade 316 2B grade for superior corrosion, chemical and abrasion resistance. The laser etched high resolution images in black can include bar and QR codes as well as variable text content. The almost indestructible image resists extreme heat, impact damage and is impervious to all but a few chemicals.

Stainless steel is non-corrosive primarily due to the presence of chromium. This layer is known as a passive layer, and it prevents oxygen from reaching the underlying steel, thereby protecting it from rust and corrosion. In addition it’s self-healing if it gets damaged as long as there is oxygen present.

316 2B = 16% Chromium 10% Nickel 2% Molybdenum Smooth 2B finish

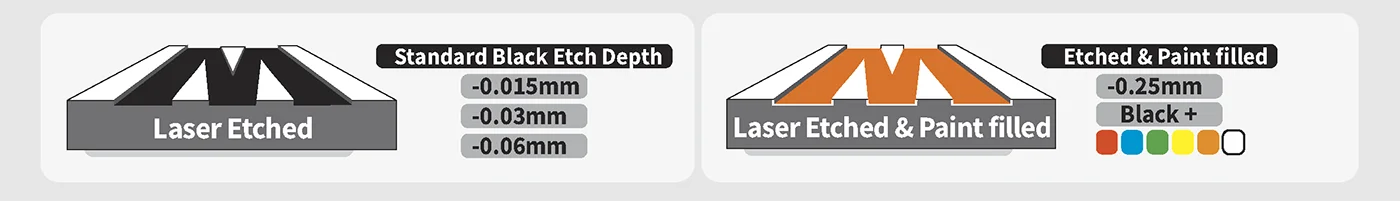

The metal surface is laser etched to four depths depending on environmental demand from -0.015mm for general industrial applications to -0.06mm deep for extreme demand. For permanent durability in constant extreme demand applications the image is deep etched to -0.25mm before optional paint filling in standard Hammerite colours.

Stainless Steel Applications

- Asset tracking labels and tags

- Military, medical, food and chemical processing

- Compliance and rating plates

- Nameplates and serial labels

- Control fascia and mimic panels

- Water and waste treatment projects

- Stainless steel valve tags

- Stainless steel custom valve tags

- Custom stainless steel asset ID tags

- Custom stainless steel labels

- 316 2B Stainless Steel for superior corrosion and unbeatable UV resistance.

- Essential in wash-down areas with 10% or greater caustic concentration.

- Withstands temperatures in excess of 400°C for extended periods.

- High contrast bar and QR codes for reliable scanning time aer time, year aer year.

- Super high-resolution laser images both front and backside.

- Laser cut in standard or custom sizes and shapes to create single and double sided tags.

- From thin to self-supporting thicknesses – available in 0.70, 0.90, 1.20 and 1.6 mm gauges.

- Add your variable info by laser, rotary engraving, traditional stamping or dot peen marking.

Stainless Steel Performance Characteristics

| GRADE | APPLICATION | PROPERTIES |

|---|---|---|

| 316 | Exterior applications subject to severe industrial or marine atmospheres; chemical; textile; photographic and paper making equipment; wine vats. | More resistant to certain corrosive conditions than the standard non-molybdenum bearing austenitic stainless steel. Suitable where protection is required from highly corrosive non-oxidising acids. Used for plant and equipment in chemical manufacture. Has moderate deep drawing and cold forming properties. Able to be welded in thickness up to 12mm without subsequent heat treatment for most applications. |

FAQ's

What’s the difference between 304 and 316 stainless steel? 304 contains 18% chromium and 8% nickel while 316 contains 16% chromium, 10% nickel and 2% molybdenum. The molybdenum is added to help resist corrosion to chlorides such as sea water.

What does 2B mean? A smooth, moderately reflective general-purpose metal finish.

Why is Stainless steel stainless? Because it is sufficiently reactive with the environment to protect itself from attack by forming an invisible passive corrosion layer. While this layer can be scratched, it will reform.